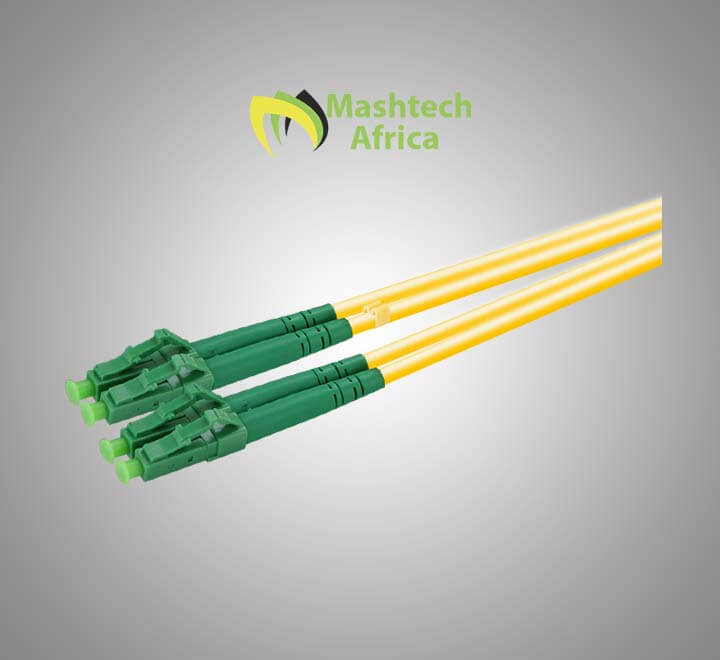

ATB With LC/ APC and LC/ APC Duplex Pigtail

8 in stock

- Free LC/APC Singlemode Fiber Optic Patch Cord sample

- PVC/LSZH environmental protection materials

- Excellent fiber core and Zirconia core

- Optical fiber patch cord Length can be customized

SKU: ATB-LC-APC D

$1.63 $1.93

8 in stock

Compare-

-

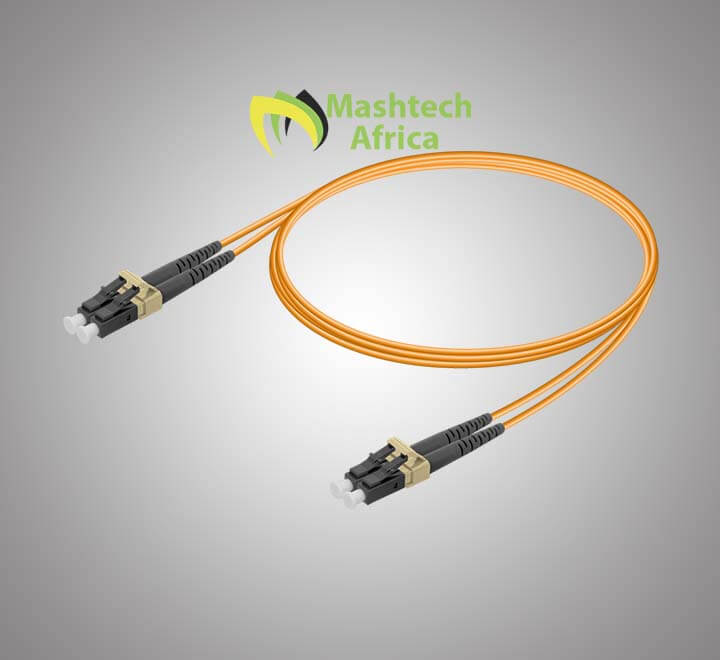

Fiber Optic Pigtail

ATB With SC/ APC Simplex Adapter

- Name: Simplex Fiber pigtails

- Fiber end-face: PC, UPC, APC

- Fiber brand: YOFC, Corning

- Fiber mode: G652D, G657A1, G657A2

- Cable diameter: 0.9mm, 1.6mm, 1.8mm, 2.0mm, 3.0mm

- Cable core: simplex, duplex, 6core,12core, 24core, 48core

SKU: FO-SC-APC-SA

SKU: FO-SC-APC-SA

SC/APC–LC/APC | Single Mode G657.A2 Duplex Patch Cord | 2.0×4.1mm is a fiber-optic patch cable capped at either end with Fiber optic connectors that allow it to be rapidly and conveniently connected to CATV, an optical switch,Optical Transceiver Modules SFP ,Media converter or other telecommunication and network equipment and switch. Its thick layer of protection is used to connect the optical transmitter, receiver, and the terminal box.

While SC (Square Connector) type connectors have 2.5 mm diameter ferule structure; LC (Lucent Connector) type connectors have 1.25 mm diameter ferule structure. The abbreviations PC, UPC and APC are definitions expressing the physical differences of the surface geometries of the connectors on the ceramic ferrules. UPC (Ultra Physical Contact) indicates that the ceramic ferule structure on the connector has an extra polished flat structure; APC (Angled Physical Contact) indicates that the ceramic ferrule structure on the connector has an extra polished 8 ° angle structure.

2.0×4.1 mm duplex patch cord cables are manufactured with ITU-T G657.A2 bend sensitive fibers, then assembled at one end with SC type; other end with LC type connectors.

Features

- Plug type coupling mechanism

- Ceramic ferrules

- Low insertion loss, high return loss

- Good in repeatability and exchangeability

- 100% Insertion, Return Loss, End Face and Interference inspection

- Excellent mechanical endurance

- High credibility and stability

- Complying with Telcordia ,GR-326-Core, IEC and RoHS Standard

Application

- telecommunication networks

- computer fiber networks

- fiber test equipment

- communication rooms

- FTTH (Fiber to The Home)

- LAN (Local Area Network)

- FOS (fiber optic sensor)

- Fiber Optic Communication System

| Brands | Fibre Optics |

|---|

Specifications

- Insertion Loss (IEC 61300-3-4-Method-B): ≤ 0.30 dB

- Return Loss (IEC 61300-3-6-Method-B): ≥ 50 dB (UPC), ≥ 60 dB (APC)

- Durability: 500 matings

- Flammability: UL94 V-0

- Operating Temperature: -40°C to +85°C

- Connector End Face Geometry: IEC 61755-3

- LC Connector Compliance: IEC 61754-20, TIA 604-10-A, RoHS

- SC Connector Compliance: IEC 61754-4, TIA 604-3, RoHS

- FC Connector Compliance: IEC 61754-13, TIA 604-4-A, RoHS

- ST Connector Compliance: IEC 61754-2, TIA 604-2, RoHS

- LSH Connector Compliance: IEC 61754 – 15, TIA 604 – 16, RoHS

SC/APC-LC/APC | Single Mode G657.A2 Duplex Patch Cord | 2.0×4.1mm

Please be free to buy our SC/APC-LC/APC | Single Mode G657.A2 Duplex Patch Cord | 2.0×4.1mm products with competitive price. The customized service and the quotation consultation are available.

Quality production Stages For SC/APC-LC/APC | Single Mode G657.A2 Duplex Patch Cord | 2.0×4.1mm

So what should be taken into consideration when choosing a ‘good’ SC/APC-LC/APC | Single Mode G657.A2 Duplex Patch Cord | 2.0×4.1mm? What are the features that one should look for that defines the quality of any connector or jumper assembly? In order to appreciate the significance of a standard compliant product, one must first understand the process of actually making an optical connector assembly and the potential problems that could occur at each of the stages.

There are three main processes in the termination of a jumper Patch Cable, Preparation, Termination and Polishing and a total of 15 steps where negligence at any one of the steps will result in an inferior jumper assembly. Each process consists of small steps, and each step requires strict Quality Control of not only the equipment used, but also how each step is carried out.

preparation of fiber cable

- Stripping of outer cable jacket

- trimming of kevlar fibers to length

- Stripping of 900um buffer

- clean bare fiber

- check fiber for damage

- mix two part epoxy

- degas epoxy

- check ferule id

termination of fiber cable

- inject epoxy and insert fiber

- crimp kevlar to back post

- crimp outer jacket

- cure connector in oven

polishing of connector end face

- cleave fiber

- Remove excess epoxy by hand or machine

- polish end-face by grinding machine

There are no reviews yet.